|

Images |

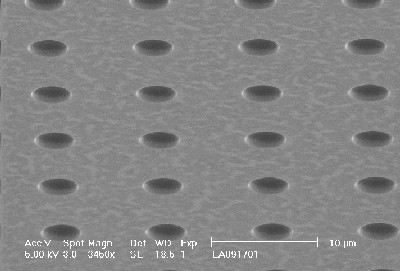

The beautiful rainbow of colors arises from light diffraction off of the millions of tiny holes etched into a GaAs semiconductor surface. The holes are backfilled with neutron reactive materials.

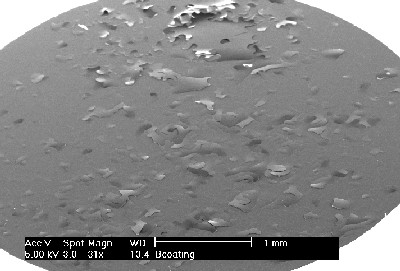

Thick coatings of boron or LiF peel off of the surface due to stress and strain.

Holes are etched into the surface with the SMART Laboratory ICP-RIE. The holes serve to reduce the surface tension of the neutron reactive coatings.

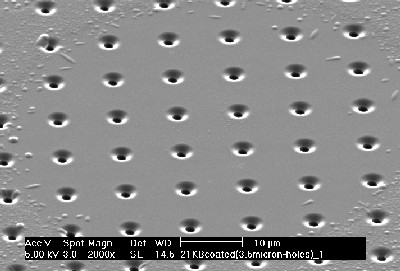

As can be seen, the film now adheres well with no cracking or peeling.

Films quite thick can be applied. Whereas before, cracking would occur with films of only 1 micron thick, shown is a well adhered film 4 microns thick.

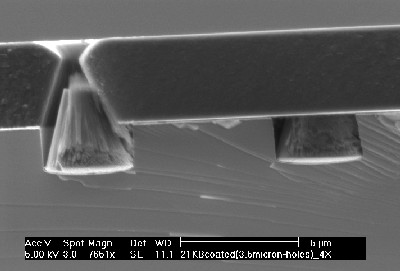

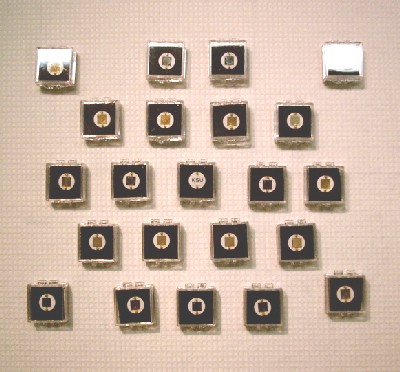

A set of perforated GaAs detectors prepared for testing. The detectors are coated with various combinations of B and LiF. After being coated with a proprietary encapsulate, these detectors will be sent to a DOE national laboratory for deployment.

[ KSU | Engineering | KATS | Webmail | Student Suggestions | Weather | Home ]

Copyright © 2003

Mechanical & Nuclear Engineering

Manhattan, KS 66506

(785) 532-4093